Who is CAXCAD?

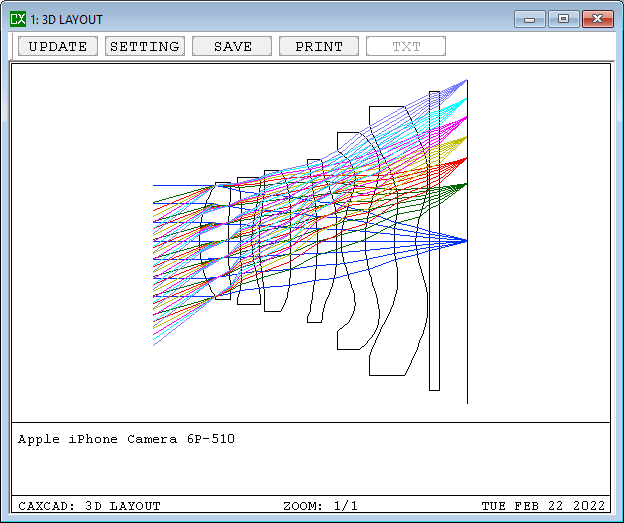

CAXCAD is one of the world's leading companies providing optical scientists and engineers with powerful professional software for Optical Design and Analysis as well as Consultancy Services, and training in Computer-Aided Lens Design world-wide. |

-

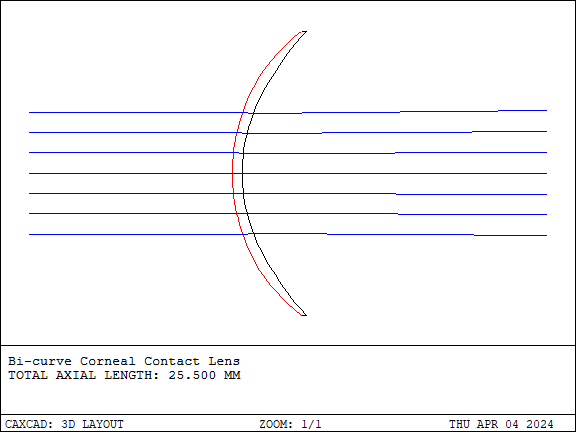

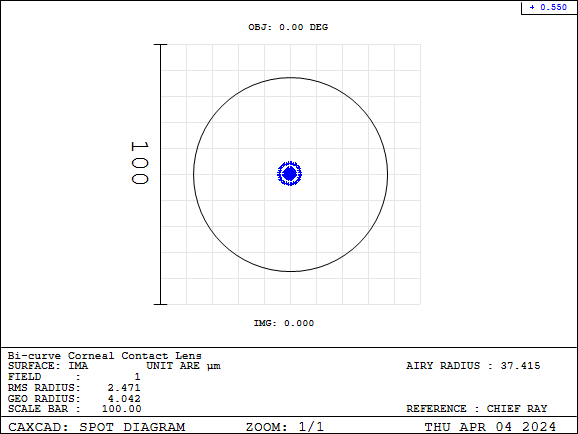

How to design the contact lens with CAXCAD?

Contact lenses are medical devices used to correct vision, placed directly on the surface of the eye or cornea unlike traditional eyeglasses. They are typically made of soft, breathable materials for comfort and adaptability. Contact lenses can correct vision problems such as nearsightedness, farsightedness, and astigmatism, providing a more natural appearance without obscuring facial features.

Read more ...

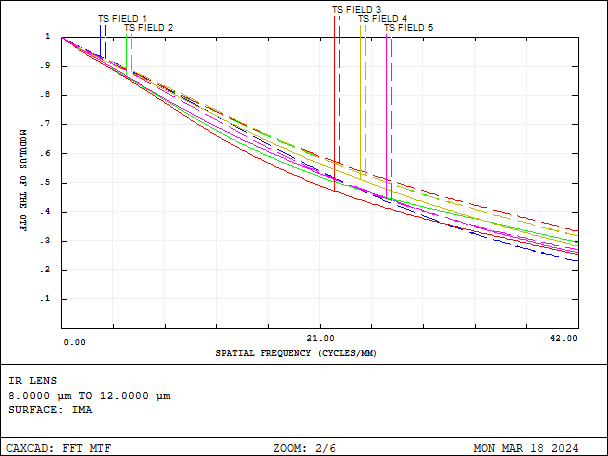

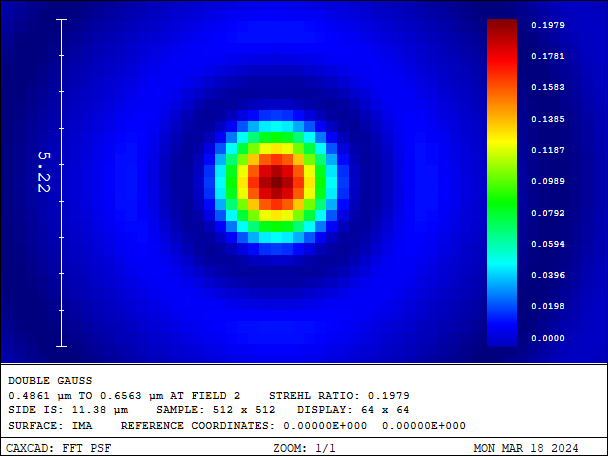

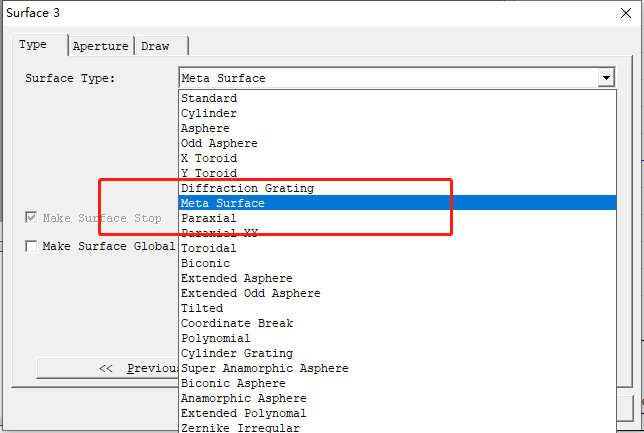

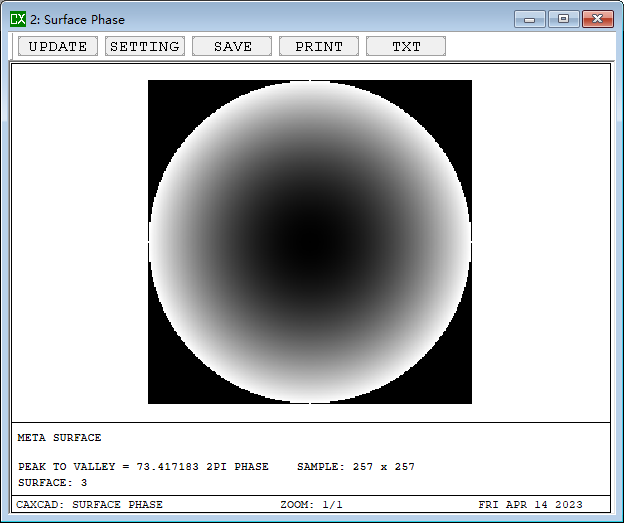

CAXCAD Meta SurfaceIn December 2022, CAXCAD joined the meta-surface surface type, supporting phase modulation of meta-surfaces and achieving fast optimization design of meta-surfaces.

|

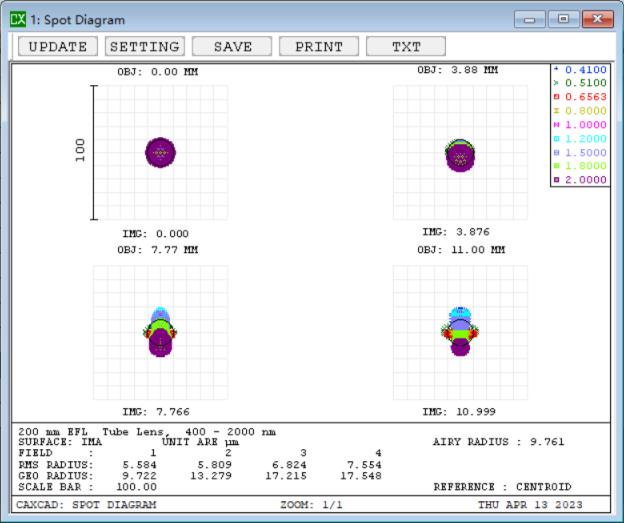

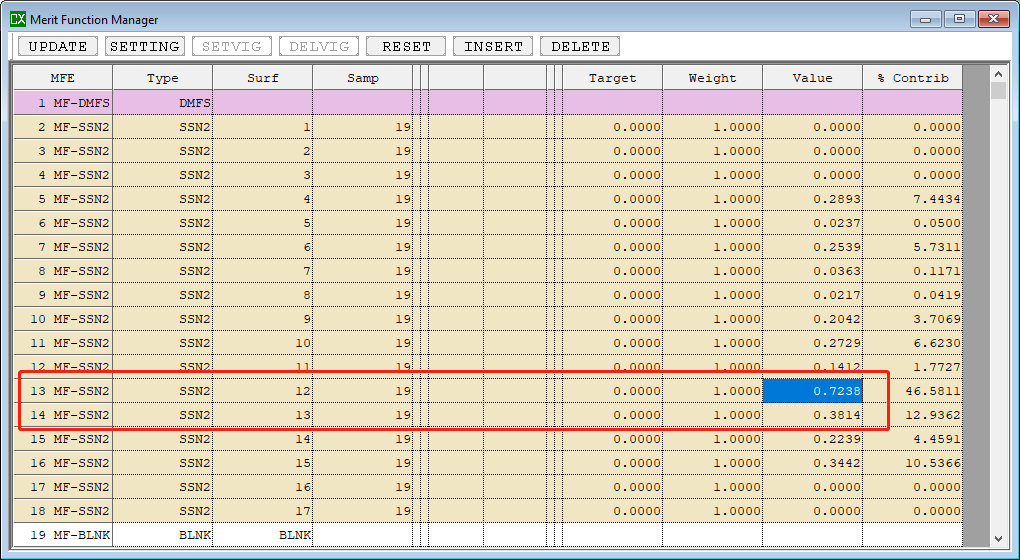

SSN2 High Yield OptimizationCAXCAD allows users to control and reduce the sensitivity of tolerances during the optimization of lenses to improve production yield. SSN2 is the core of CAXCAD's high-yield optimization, which introduces manufacturing sensitivity into the evaluation function.

|

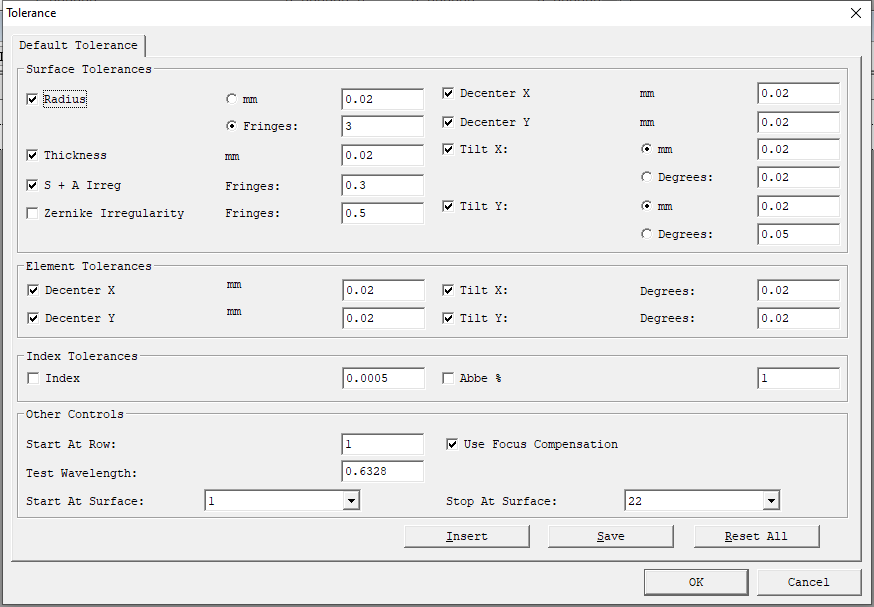

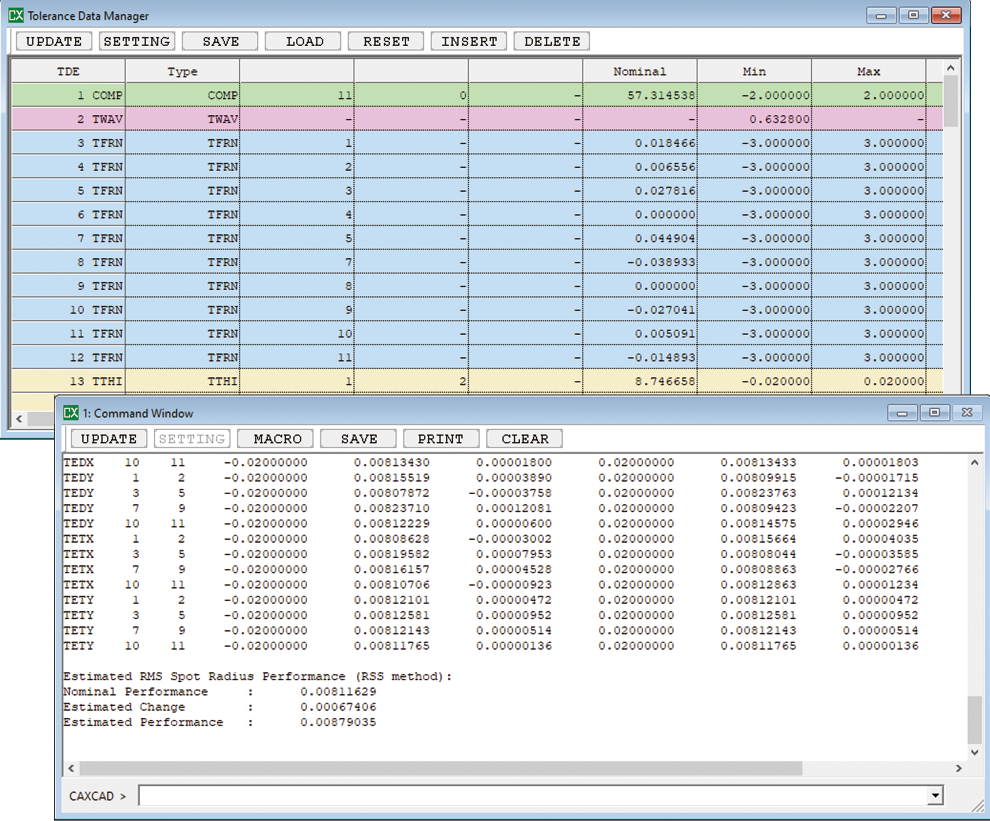

ToleranceCAXCAD's tolerance analysis feature, which is sensitive to lens manufacturing, can help users better control dimensional variations during the design process, thereby reducing manufacturing defects and product failure rates. CAXCAD also provides a tolerance instruction set, which allows users to customize the instructions and parameters required during the tolerance analysis process. This feature enables users to conduct tolerance analysis more flexibly to meet different design and manufacturing requirements.

|