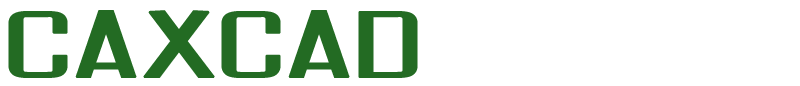

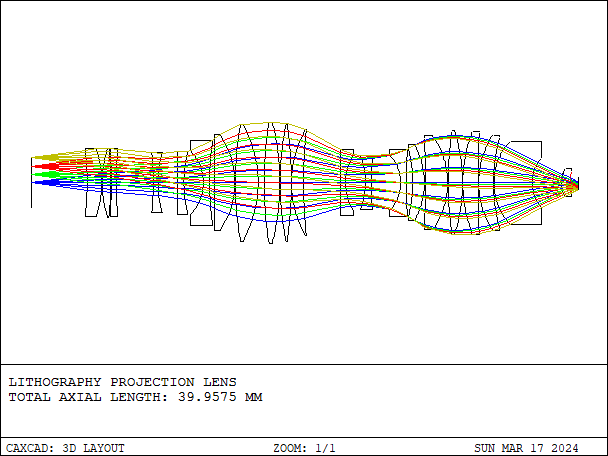

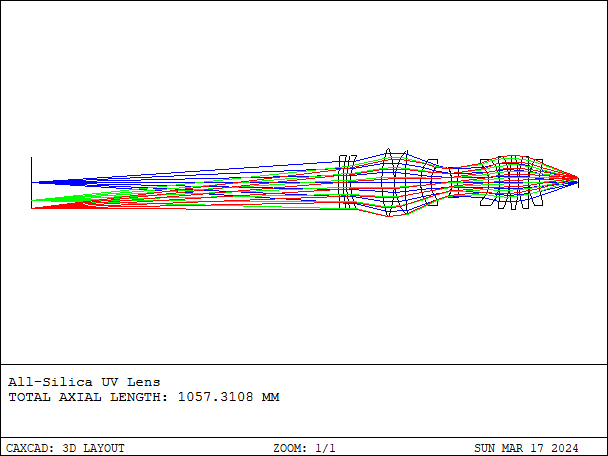

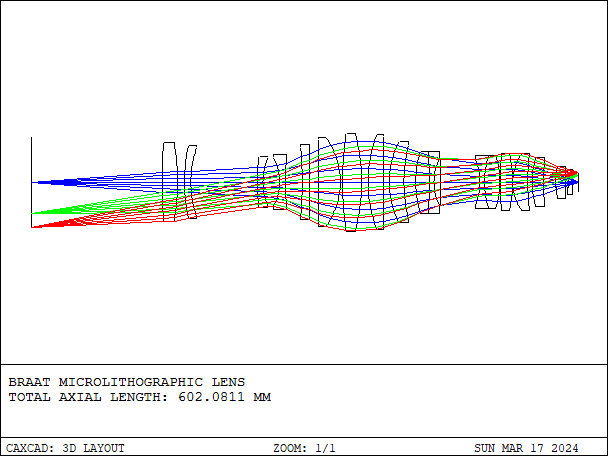

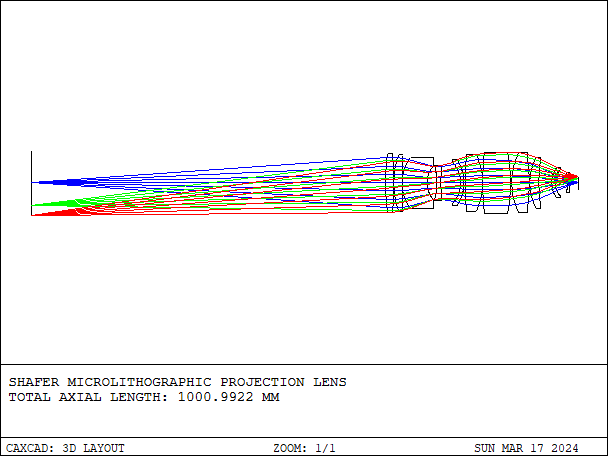

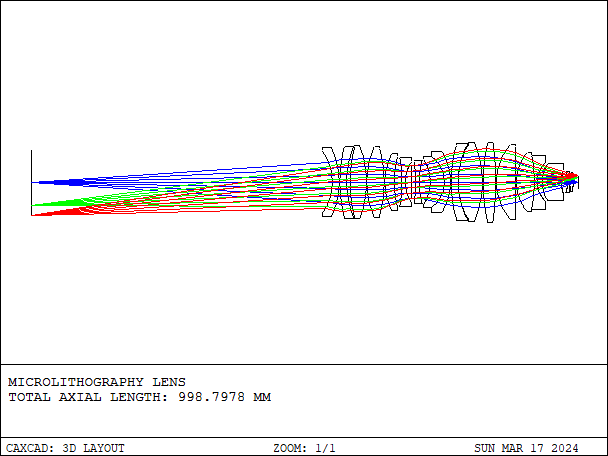

Ultraviolet lithography lens is an optical component specialized for the lithography process in semiconductor manufacturing.

In semiconductor manufacturing, ultraviolet lithography is a crucial step used to transfer patterns from a chip onto a photosensitive resist layer for subsequent chemical etching or deposition steps.

The role of ultraviolet lithography lens is to focus the light field generated by the projection source onto the photoresist layer while maintaining the desired resolution and pattern quality. These lenses typically utilize ultraviolet light sources with wavelengths usually ranging from 250 to 450 nanometers, as the short wavelength of ultraviolet light enables higher resolution.

Key features of ultraviolet lithography lens include:

1. High resolution: The short wavelength of ultraviolet light allows for higher resolution lithography patterns, enabling smaller chip structures.

2. Flat wavefront: Ultraviolet lithography lenses need to maintain a flat wavefront of the pattern to ensure uniform projection across the entire chip surface.

3. Large field of view: Ultraviolet lithography lenses typically require a large field of view to cover the entire chip area in a single exposure.

4. Low distortion: Lens designs aim to minimize aberrations and distortions to ensure the projected patterns maintain shape and accuracy.

Ultraviolet lithography lenses are critical optical components in semiconductor manufacturing, requiring high precision and specialized knowledge in their design and manufacturing. They play a crucial role in the success of chip fabrication, directly impacting the final resolution and performance of the chips.